- Processing

- Processing PDF

With the rapid development of China’s economy and the improvement of people’s living standards, as a guarantee of food safety, food quality requirements have become the focus of widespread concern. Microwave thawing is a non-drip state in which the frozen product is heated to -2 degrees Celsius using microwave penetration and selective heating characteristics of -42 to -18 degrees Celsius.

Compared with existing technology, industrialized microwave thawing equipment has the following advantages:

Compared with existing technology, industrialized microwave thawing equipment has the following advantages:

1. Industrialized microwave thawing equipment has reasonable structure design and convenient operation. It adopts a 915MHz microwave energy generator. The combined power of the equipment can reach up to 150kW, and the processing capacity can reach 10t per hour, which can meet the demand of industrial equipment for production output.

2. The high-power rotating waveguide feed port can solve the high-power and reliable feeding energy of the equipment and facilitate the uniform distribution of the electric field on the surface of the defrosted material.

3. It adopts a high-power microwave generator with high power control accuracy, rich features, stable and reliable.

4. PLC intelligent control systems can realize the automatic unfreezing function of unattended equipment and take the corresponding process for thawing treatment for different materials.

5. The material conveying system has an opening height of 300mm suppressor at the inlet and outlet, which realizes the microwave leakage protection during the equipment’s continuous operation. The belt speed of the material conveying system is infinitely adjustable, different operating speeds can be adjusted according to different treatment processes.

6. With metal detection and ejection mechanism, the metal-containing material package can be screened out at the source end with high safety. Compared with the traditional thawing method, microwave thawing equipment has the advantages of low investment, high efficiency, low operating cost, high product quality, convenient control, and operation.

Structural composition of industrialized microwave thawing equipment:

Microwave thawing equipment, including a frame, a microwave cavity mounted on the frame, a rotary feed waveguide mounted on the microwave cavity, a rotary feed waveguide connected to the microwave transmission system, a microwave transmission system connected to the microwave head. The microwave head is connected to a microwave energy generator, and the microwave energy generator is connected to the control system.

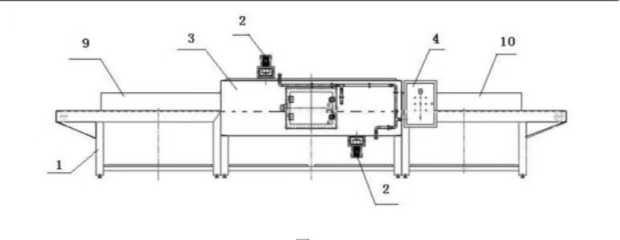

Schematic diagram of industrialized microwave thawing equipment

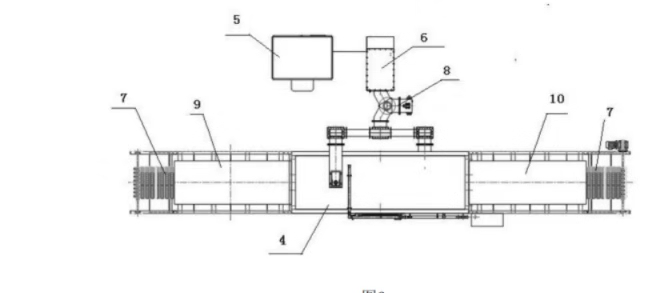

The industrialized microwave thawing equipment a frame (1), a microwave cavity (3) mounted on the frame (1), a rotary feed waveguide (2) mounted on the microwave cavity (3), and a rotary feed waveguide ( 2) connected to the microwave transmission system (8), the microwave transmission system (8) is connected to the microwave head (6), the microwave head (6) is connected to the microwave energy generator (5); the microwave energy generator (5) and the control system (4) Connected. A material conveying system (7) is installed on the frame, and the material conveying system (7) passes through the microwave cavity (3).

Overview of the workflow of industrialized microwave thawing equipment:

The system passes through the microwave cavity. A microwave feed port suppressor and a microwave discharge port suppressor are installed at the inlet end and the outlet end of the microwave cavity.

Industrialized microwave defrosting machine, the control system includes PLC and touch screen connected with PLC. The touch screen is used as the upper computer to set the operation, alarm, stop, and other instructions, establish the defrosting material process package database. According to different materials, the corresponding process is executed; the microwave generator is controlled by the Ethernet configuration. The frequency converter connected to the motor is controlled as the device transmission. The material signal detected by the photoelectric switch is collected. The microwave power is turned on according to the transmission speed to realize transmission open, automatic defrost with the material and automatic standby without material unattended mode.

A material conveying system 7 is installed on the frame, and the material conveying system 7 passes through the microwave cavity 3. The inlet and outlet end of the microwave cavity 3 are equipped with a microwave feed port suppressor 9 and a microwave discharge port suppression 10.

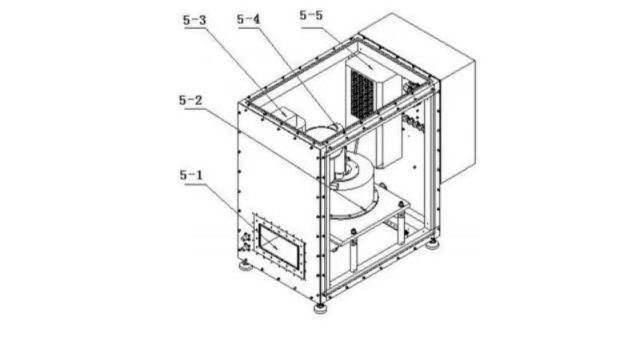

The microwave energy generator 5 includes a microwave power cabinet and a microwave output cabinet. The microwave output cabinet comprises a 915 MHz magnetron 5-4, a filament transformer 5-3, an electromagnet 5-2, a cooling device 5-5, and an excitation chamber 5-1. The magnetron 5-4 is located at the electromagnet 5-2 inside, and the 5-2 is mounted on the excitation chamber 5-1. The magnetron 5-4 is driven by the microwave power source. The microwave is generated by the filament transformer 5-3 and the electromagnet 5-2. The microwave is transmitted in the waveguide via the excitation chamber 5-1, wherein the cooling device 5-5 dissipates heat to the microwave output cabinet.

Our service:

1. Our Leader microwave equipment company’s industrial microwave thawing equipment is guaranteed for one year.

2. Welcome to contact us if you encounter any installation problems during use. We will provide you with timely assistance.

3. Our company can produce a variety of models to meet the different needs of customers.

Our Leader microwave equipment company is committed to producing first-class equipment with high efficiency and energy saving.

Welcome your visit, and look forward to cooperating with you!

Compared with existing technology, industrialized microwave thawing equipment has the following advantages:

Compared with existing technology, industrialized microwave thawing equipment has the following advantages:

Meat microwave thawing equipment Technologies and Processing PDF Download

Meat microwave thawing equipment Technologies and Processing PDF Download