- Processing

- Processing PDF

Microwave thawing makes use of polar molecular vibration to generate elastic collision with surrounding molecules, frictional heat generation, its heating method is generated from the inside of the product material. The way of tempering the food has advantages of low production cost, high efficiency, no bacterial growth of the product, and a small footprint unmatched by other methods. As a flow production line, industrial microwave thawing equipment is generally long and large, and safety is also important.

Advantages of Seafood microwave thawing machine:

Advantages of Seafood microwave thawing machine:

1. Microwave thawing machine, the metal shielding door can reflect the microwave that is leaked into the feeding suppression chamber and the discharge suppression chamber into the device, further, in the premise of the total length of the device, the length of the feed suppression chamber and the discharge suppression chamber can be greatly reduced, and the length of the heating chamber can be increased, thereby increasing the effective space utilization rate

2. Our Seafood microwave thawing machine, the metal shielding door reflects the microwave in the feed suppression chamber or the discharge suppression chamber and irradiates the material in the feed suppression chamber or the discharge suppression chamber to avoid the loss of microwave energy, increase energy efficiency and improve production capacity

3. Microwave thawing equipment is convenient to use. The structure of the microwave thawing equipment adopts a detachable connection, enabling the device to be decomposed and packaged after being commissioned in the production workshop. It can directly be installed after arriving customer’s site, reducing the installation time of the customer, reducing the working intensity of the installation personnel, reducing the impact of on-site welding distortion on the equipment.

4. Seafood microwave thawing machine, in the premise of the total length of the equipment, increases the length of the heating chamber, increases the effective space utilization, reduces equipment costs, increases the equipment thawing capacity, sets the slot antenna and polygon heating cavity. The material is thawed more evenly, the loss of microwave energy can be avoided, and the energy utilization rate is increased.

5. The use method of the seafood microwave thawing machine can effectively prevent microwave leakage and make the microwave thawing more uniform, improve the thawing efficiency, and increase the energy utilization rate.

Seafood microwave thawing machine

Structure of the seafood microwave thawing machine:

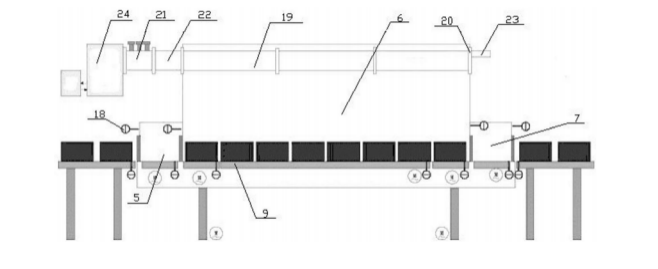

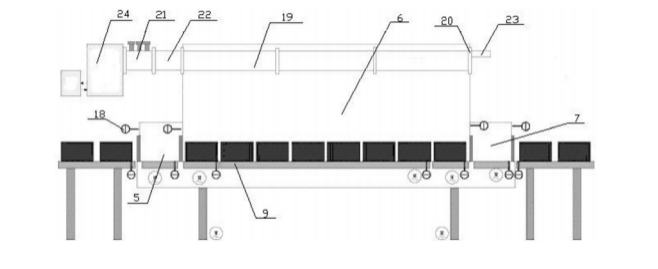

1.bracket, 2-first connection section, 3-second connection section, 4-third connection section, 5-feed suppression chamber, 6-heating chamber, 7-discharge suppression chamber, 8-transport chain, 801-feed chain network, 802-feed adjustment chain network, 803-main transmission chain network, 804-discharge adjustment chain network, 805-outlet chain network, 9-chain net support mounting plate, 10-first inner side Screen door mechanism, 11-first outer screen door mechanism, 12-second inner screen door mechanism, 13-second outer screen door mechanism, 14-shield door, 15-shield door slide, 16-transmission mechanism, 1601- Transmission cylinder, 1602-transmission rack, 1603-support wheel, 1604-commutation gear, 1605-lifting rack, 1606-connecting slide, 17-reduction motor, 1701-feed chain transmission motor, 1702-feed Chain net adjustment motor, 1703-main chain transmission motor, 1704-distribution chain adjustment motor, 1705-distribution chain transmission motor, 18-photodetector, 19-slot antenna, 1901-porosity, 20-fixing, 21-mixer, 22-waveguide, 23-arc sensor, 24-microwave generator, 25- suspender

Our quality service:

1. We provide customers with superior mechanical equipment and have a variety of machines, including water mist microwave thawing equipment.

2. Our Leader Microwave Equipment Company has an excellent sales team, foreign trade documentation team, after-sales service team, to provide you with the most complete service.

3. The company’s mechanical equipment warranty period is one year.

Over the years, our company has been committed to the manufacture and sale of high-quality microwave equipment and has many old customers. We have a good reputation and public praise, if you want to start a new business, please contact us at any time.

Looking forward to collaborating with you.

Advantages of Seafood microwave thawing machine:

Advantages of Seafood microwave thawing machine: Seafood microwave thawing machine Technologies and Processing PDF Download

Seafood microwave thawing machine Technologies and Processing PDF Download