- Processing

- Processing PDF

Automatic fast food box lunch heating sterilizer equipment is a prepackaged food secondary temperature returning sterilization equipment.

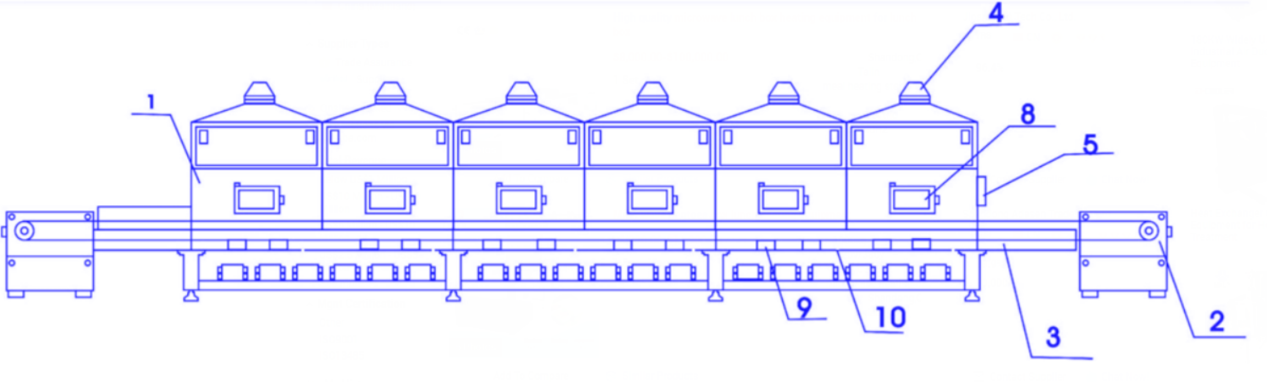

Microwave Heating Equipment For Lunch Box includes microwave heating chamber, microwave generator, microwave suppressor, material conveyor, control and detector, moisture exhauster, cleaning door, cleaning brush, small hole, moisture drain, material conveying. The unit passes inside the microwave heating chamber and is fixed, with a microwave suppressor fixed on both sides of the material conveyor. An exhaust heat sinks fixed on the upper side of the microwave heating chamber, an infrared radiation thermometer, and control and detection devices are installed at the discharge of the microwave heating chamber. A special cleaning door is arranged outside the microwave heating chamber.

The problem of traditional fast food:

1. The food should be kept at a temperature above 70 °C when the pan is baked to ensure the food’s safety performance. Through the heat transfer of the temperature, it will take no more than two hours to deliver fast food by car, so the limited distribution range can only be a short distance.

2. Due to the huge volume of production, the production plant has to produce sufficient quantities of meals in a short period to meet the supply. We have to sell the food first to ensure its freshness and safety, not as a general commodity, limiting the transportation of goods.

3. Because the food is manually boxing and packaging after the pot is finished. It is easy to breed bacteria and pose a threat to customers’ health.

Advantages of LD1901 automatic fast food box lunch heating sterilizer equipment:

Advantages of LD1901 automatic fast food box lunch heating sterilizer equipment:

1. LD1901 automatic fast food box lunch heating sterilizer equipment adds a temperature that is returning sterilization step after the traditional packaging. Killing bacteria by the high temperature of microwaves, which guarantees the health of customers.

2. Use LD1901 automatic fast food box lunch heating sterilizer equipment to put the food into the cold storage for refrigerating, and then reheat and sterilize the food when needed to ensure the freshness and health of the food. According to the reservation, the food that the customer needs can be prepared in advance put into the cold storage, and then taken out directly when needed. The equipment will be warmed and sterilized to keep the food fresh and healthy. It guarantees the normal supply of the company and prolongs the preservation time of the food.

3. LD1901 automatic fast food box lunch heating sterilizer equipment microwave heating chamber box is a tunnel type box type. The heating chamber has a large capacity, it can simultaneously sterilize and heat a large amount of food, and the sterilization heating speed is fast. LD1901 automatic fast food box lunch heating sterilizer equipment is fixedly mounted on both sides of the material conveyor with a microwave suppressor, which can suppress the outward microwave scattering and ensure the staff’s safety. The infrared radiation thermometer is installed in the microwave heating chamber discharge port. The position can test the temperature of the heated food to ensure the quality of the heating.

Scientific design of LD1901 automatic fast food box lunch heating sterilizer equipment:

1. The microwave generator of LD1901 automatic fast food box lunch heating sterilizer equipment is a tunnel type box type, and the whole machine has a beautiful appearance. The utility model has a special cleaning door, which can clean at any time to keep cleaning in the microwave generator box. Ensure the food is clean and healthy.

2. The bottom of the microwave generator box is provided with a small hole to achieve the relative balance between the airflow and the wind pressure. The upper side of the microwave generator is fixedly equipped with a moisture discharge heat exchanger, which can discharge the heat inside the microwave generator. Improve and guarantee the temperature inside the microwave generator to ensure that the equipment can run continuously for a long time.

3. LD1901 automatic fast food box lunch heating sterilizer equipment can carry out the temperature and anti-virus and fully guarantee food safety in the lunch box.

Bento Lunch Box Meal Microwave Reheating Machine for Minus 18 to 80 Celsius Degree components includes:

Microwave heating chamber (1), microwave generator (7), microwave suppressor (2), material conveyor (3), control and detector (6), dehumidifier heat exchanger (4), cleaning special door (8 ), cleaning brush (9), small hole (10), moisture discharge port (11), material conveyor (3), through microwave heating chamber (1), material conveyor (3), microwave suppressor (2) , microwave heating chamber (1), heat extractor (4), infrared radiation thermometer (5), control and detector (6), microwave heating chamber (1), cleaning special door (8), material conveyor ( 3), cleaning brush (9), moisture exhauster (4), moisture drain (11)

Application of LD1901 automatic fast food box lunch heating sterilizer equipment:

The fast-food company has a large production volume, fast transportation, and food processing all in aseptic conditions. LD1901 automatic fast food box lunch heating sterilizer equipment application:

The fast-food company has a large production volume, rapid transportation, and food processing all under aseptic conditions. It is safe and convenient to be accepted by customers. Traditional boxed foods are divided into basic steps, such as making, packing, and packaging. The preparation is generally done in aseptic conditions. It is impossible to cause bacterial proliferation, but in the packaging and packaging process, even if you are involved in manpower, even if you are careful. It also causes more or less secondary pollution of food.

LD1901 Conveyor Belt Microwave Heating Equipment For Lunch Box can process food according to customer needs, and pack and package the cooked food.

Then put the cooked food in cold storage for refrigeration, take out the refrigerated packaged food when the customer needs it. Put into the microwave pre-packaged food secondary temperature returning sterilization equipment for high-temperature sterilization.

Place the lunch box that needs to be processed on the side of the material feeder inlet. The conveyor of the material conveyor feeds the lunch box into the microwave heating chamber, and then the microwave generator generates microwaves, the microwaves enter the microwave heating chamber 1. The microwave heating chamber generates high temperature, heats, and sterilizes the food. The hot gas and moisture generated during the mechanical operation are discharged into the microwave heating chamber through the heat dissipation holes and the moisture discharge port of the moisture discharge heat exchange. The microwave suppressor suppresses the outward diffusion of the microwave. The infrared radiation thermometer at the external outlet of the microwave heating chamber tests the temperature of the heated food. If the heated food does not reach 70 ° C, the infrared radiation thermometer automatically gives an alarm, the control and detector act on the microwave generator to adjust the microwave. The staff reheated the lunch box. Finally, the heated and standard food is delivered to the customer’s location.

Technical parameters of LD1901 automatic fast food box lunch heating sterilizer equipment:

Technical parameters of LD1901 automatic fast food box lunch heating sterilizer equipment:

| Daily capacity | 8T-10T | Leakage value | ≤3mw/m³ |

| The total power | 30KW/h | Microwave frequency | 2450/915MHz |

| Transmission speed | 0-5m/min(adjustable) | Cooling method | Water cooling |

| Sterilization ability | 300-400kg/h | Working method | Completely continuous. |

| Size | 10500x840x1800mm | heating method | Electricity |

Our service:

Customers can call us or come to our factory for equipment testing to produce satisfactory products.

1. We offer special customized equipment for special users.

2. We use wooden box packaging equipment to avoid shipping damage.

3. Equipment warranty for one year.

Leader Microwave Equipment Company has won many users’ favor with its excellent equipment and warm and perfect service. Our customers come from many countries and regions at home and abroad, we are honored for this and are committed to providing more perfect machinery. If you need our automatic fast food box lunch heating sterilizer equipment or seafood microwave thawing machine. Welcome to contact us at any time.

Advantages of LD1901 automatic fast food box lunch heating sterilizer equipment:

Advantages of LD1901 automatic fast food box lunch heating sterilizer equipment: LD1901 Automatic fast food box lunch heating sterilizer equipment Technologies and Processing PDF Download

LD1901 Automatic fast food box lunch heating sterilizer equipment Technologies and Processing PDF Download