- Processing

- Processing PDF

Microwave thawing equipment is used to thaw and preserve meat (beef, mutton, prawns, chicken, duck) foods during food thawing processing.

Some of the drawbacks of traditional defrosting equipment:

Some frozen foods, such as quick-frozen foods, are generally stored in an environment below -18 °C and need to be thawed before production. The common methods of thawing are as follows:

1. The ordinary water bath method is also called natural thawing. It is to put the frozen goods directly into normal temperature water or cold water for thawing. It usually takes several hours to ten hours or even several days to achieve thawing. The quality of frozen products will be damaged due to excessive time.

2. There is a commonly low-temperature thawing method that the frozen items are thawed in a fresh-keeping freezer at TC~4 °C. Although this method is fresh, it takes a long time.

The above thawing method mainly has the disadvantages of slow thawing speed and low efficiency, which needs improvement.

Advantages of meat microwave thawing machine:

Advantages of meat microwave thawing machine:

The microwave food thawing equipment solves the problems of slow thawing speed and low efficiency in existing technology. Firstly, the microwave thawing machine can decompress the defrosting chamber by a decompression device. Secondly, irradiate the defrosted material with microwaves by a magnetron for the first thawing. The second thawing is carried out by the air feeder and pressure relief device, which has a fast thawing speed and high efficiency and can guarantee the quality of thawed materials.

Meat microwave thawing machine

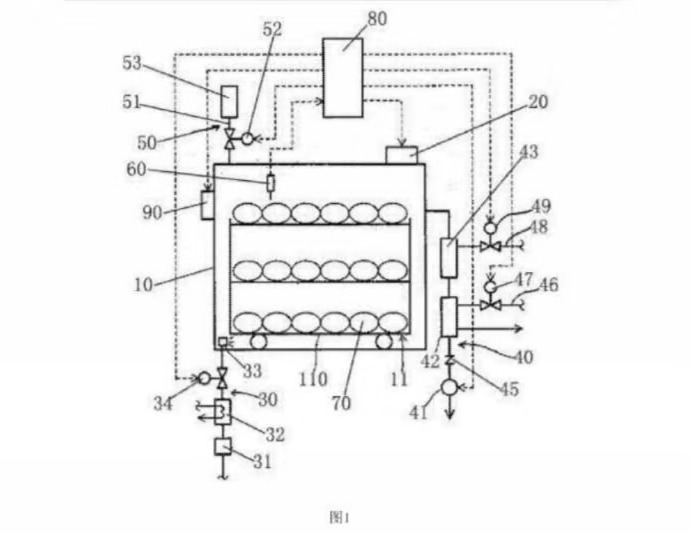

The microwave meat thawing machine includes a thawing chamber for accommodating the thawed material, a magnetron disposed on the thawing chamber for microwave irradiation in the defrosting chamber, a microwave tube disposed under the defrosting chamber and used for supplying steam to the defrosting chamber, a gas supply device disposed below the thawing chamber and used to supply steam to the defrosting chamber. This decompression device exhausts the defrosting chamber to keep it at low pressure. It is a repressure device for introducing gas into a decompressed thawing chamber to restore air pressure, a pressure detector for determining the internal pressure in the thawing chamber. This controller controls the thawing condition of the thawed object in the defrosting chamber based on the signal output from the pressure detector.

The gas supply device includes a water softener for supplying soft water, a reboiler connected to the water softener, and processing the supplied soft water into steam, a spray head connected to the reboiler through the gas pipe ejecting the steam of the reboiler. The pressure reducing device comprises a vacuum pump, a heat exchanger connected to the vacuum pump, a steam pump connected to the heat exchanger, wherein the steam pump communicates with the defrosting chamber through a pipe. The heat exchanger is connected with a cold water supply pipe, and The cold water supply pipe is provided with a water supply valve. The steam pump is connected with a steam pipe connected to a boiler, and the steam pipe is provided with a steam valve.

The gas supply device 30 includes a water softener 31 for supplying soft water, a reboiler 32 connected to the water softener 31 processing the supplied soft water into steam, a steamer connected to the reboiler 32 through the gas pipe, the steam of the reboiler 32. The sprinkler head 33 is provided with an air valve 34 on the gas pipe connected between the reboiler 32 and the head 33. The head 33 is disposed in the defrosting chamber 10, and the gas valve 34, the reboiler 32, and the water softener 31 are disposed outside the defrosting chamber 10. The gas valve 34 can be a proportional valve that can regulate the amount of steam passing through.

Microwave food thawing equipment

Mechanical composition of microwave meat thawing equipment:

10. Thawing chamber; 20, magnetron; 30, gas supply device; 40, pressure reducing device; 50, recompression device; 60, pressure detector; 80, controller; 70, thawed; 110, bracket; 31, water softener; 32, reboiler; 33, nozzle; 34, gas valve; 41, vacuum pump; 42, heat exchanger; 43, steam pump; 45, check valve; 46, cold water Supply pipe; 47, water supply valve; 48, steam pipe; 49, steam valve; 51, external gas introduction pipe; 52, re-pressure valve; 53, sterilization filter equipment; 90, display.

Customer visit

Our Leader Microwave Equipment Company is one of the best food microwave equipment manufacturers, producing a variety of mechanical equipment, including a seafood microwave thawing machine. Our company has many years of professional manufacturing experience. Our company also has an excellent mechanical manufacturing team, trade services, and after-sales service team. Because our machinery and equipment focus on high quality, perfect after-sales service, we have won the praise of our customers. If you are interested in our machinery and equipment, please consult at any time.

Looking forward to your call and email!

Advantages of meat microwave thawing machine:

Advantages of meat microwave thawing machine:

Meat microwave thawing equipment Technologies and Processing PDF Download

Meat microwave thawing equipment Technologies and Processing PDF Download