Microwave defrosting refers to the method of defrosting frozen food under the action of certain frequency electromagnetic waves. Compared with traditional natural defrosting, water immersion, or water drenching defrosting. It has prominent advantages of short time, uniform internal and external heat, reduced meat loss, no loss of nutrients, a clean environment, and high product hygiene standards.

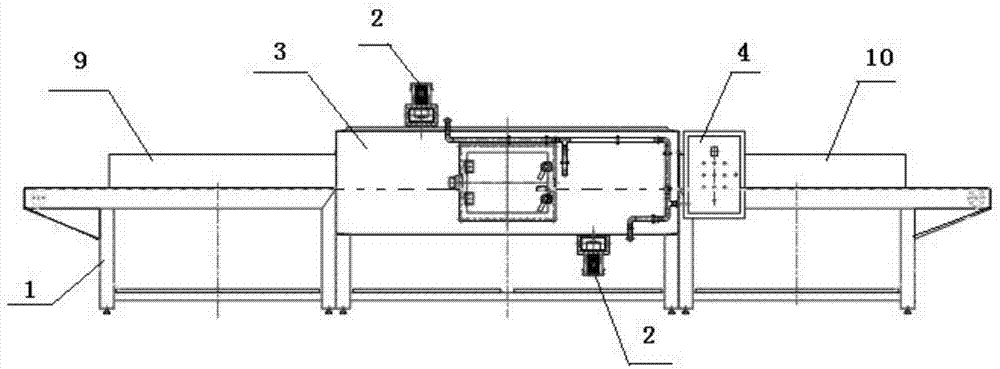

Frozen chicken microwave defrosting machine is a kind of special equipment for defrosting frozen food. The microwave defrosting equipment is composed of a tunnel-type microwave generator box and a conveyor belt. To adapt to different sizes of meat defrosting required speed, the speed of transmission using frequency control.

Advantages of frozen chicken microwave defroster:

- The refrigeration system of frozen chicken microwave defrosting machine: fully automatic control of refrigeration temperature, ensure the quality of frozen products, keep the product fresh, efficient, and safe.

- Circulating air system of frozen chicken microwave defrosting equipment: it is made of 304 stainless steel. The fan adopts a high-quality axial flow fan, which is safe and stable to ensure food hygiene requirements.

- PLC automatic control system of frozen chicken microwave defrosting machine: humanized control, high automation precision, accurate temperature curve display, automatic control, and various defrosting methods.

- Microwave frozen chicken thawing machine consumes less time and has good product quality. Thawing tuna, for example, can be thawed and cut by a knife, microwave thawing takes only 28.5 minutes, while air thawing takes 16 hours.

- Microwave defrosting equipment for frozen chicken has a germicidal effect, inhibits the growth of microorganisms, and defrosting food is not contaminated.

- The microwave frozen chicken defrosting mechanical device occupies a small area, saving site investment and labor costs.

- Microwave frozen chicken defrosting machine can realize continuous production, which will not generate high temperature, reduce shutdown and cooling time, and greatly improve production efficiency.

Frozen chicken microwave defroster product information

| Function | Defroster |

| Capacity | 120 – 1800 Kg / h |

| Control system | PLC |

| Material | Stainless Steel |

| Color | Silver grey |

Microwave defrosting is an ideal defrosting method for frozen meat, especially imported beef and mutton (microwave defrosting machine for beef and mutton), pork, chicken, and seafood products. Microwave defrosting will not cause any damage and product loss.

Frozen chicken microwave defroster equipment parameters

| Model number | Power

(kw) |

Dehydration ability (kg / h) |

Sterilization ability

(kg / h) |

Size | |

| DL-12KWSP | 12 | 12 | 120-150 | 7010 * 840 * 1750 | |

| DL-20KWSP | 20 | 20 | 190-240 | 9350 * 840 * 1750 | |

| DL-30KWSP | 30 | 30 | 300-380 | 11690 * 840 * 1750 | |

| DL-40KWSP | 40 | 40 | 390-500 | 10520 * 1060 * 1750 | |

| DL-50KWSP | 50 | 50 | 500-630 | 11690 * 1060 * 1750 | |

| DL-60KWSP | 60 | 60 | 600-750 | 12860 * 1060 * 1750 | |

| DL-70KWSP | 70 | 70 | 700-870 | 14030 * 1060 * 1750 | |

| DL-80KWSP | 80 | 80 | 800-1000 | 12680 * 1200 * 1750 | |

| DL-100KWSP | 100 | 100 | 1000-1250 | 15200 * 1200 * 1750 | |

| DL-150KWSP | 150 | 150 | 1500-1850 | 21050 * 1200 * 1750 | |

| DL-200KWSP | 200 | 200 | 2000-2500 | 25050 * 1200 * 1750 |

Examples of traditional defrosting processes:

1. Air defrosting

Move frozen meat to defrost room, heat exchange defrost by air medium, and frozen meat.

This is an original defrosting method with low cost and convenient operation, but the defrosting speed is slow.

When the meat is thawed at a high temperature, there is a large temperature difference between the surface and the inside of the meat, causing discoloration, dryness, dust contamination, and the growth of bacteria. When thawing with air, a certain wind speed, temperature, humidity, and other factors must be considered to ensure product quality.

2. Liquid defrosting

The liquid defrosting method is mainly the method of water immersion or spray.

A large amount of water used causes some of the protein and essence to be lost, changing the color and odor. When the water temperature is 10 ℃, thaw 20 h; water temperature is 20 ℃, thaw 10 ~ 11 h, and thaw the finished meat, due to the moist surface, need to be placed in the air temperature of about 1 ℃ under the conditions of drying.

Working principle of frozen chicken microwave defroster:

Frozen chicken microwave defrosting machine heating frozen goods rapidly, which at -42 to -18 degrees, so that both inside and outside of the frozen defrosting at the same time to -2 degrees Celsius state without water dripping.

Using microwave heating, low energy consumption, the small temperature difference between inside and outside, the material is basically intact during defrosting, defrosting speed, can effectively keep the original flavor, color, and nutrition of food.

At the same time has a strong bactericidal effect. With the continuous development of microwave technology, we believe that microwave defrosting devices and microwave drying equipment and other advanced microwave equipment will be preferred in factory processing machinery and equipment.