- Processing

- Processing PDF

Some frozen items such as quick-frozen foods are generally stored in an environment below -18 °C and need to be thawed before production. If it adopts improper thawing methods, the quality and taste of the food will be affected.

Rapid low-temperature microwave thawing equipment uses cold and wet airflow and the low-temperature environment as the microwave thawing environment. In the thawing process, the cold, wet airflow forms a layer of frost film on the surface of the frozen material. After the formation of frost film, due to microwave heating, the internal temperature of frozen material rises, the frost film melts and destroys from inside to outside. At the same time, there is new cold moisture condensation outside, the formation of dynamic balance, so that the frost film always exists in the frozen material surface, and keep low temperature. It protects the jelly’s surface so that it is not cooked or scorched, and achieves uniform thawing inside and out when thawing. When used for thawing frozen food, it can play the effect of fresh thawing.

Compared with traditional thawing equipment, fast low-temperature microwave thawing equipment has many advantages:

Compared with traditional thawing equipment, fast low-temperature microwave thawing equipment has many advantages:

1. The ordinary water bath method of defrosting is to put frozen goods directly into normal temperature water or cold water for defrosting. It generally takes a few hours or even a few days to achieve thawing, which can damage the quality of the frozen product due to excessive time.

2. There is also a commonly used low-temperature thawing method; that is, the frozen articles are thawed in a fresh-keeping freezer of TC~4 °C, although the method can keep fresh, the time is longer.

The traditional thawing method mainly has the problems of slow thawing speed and low efficiency. At present, there is a thawing method in a microwave oven. In general, the frozen materials are directly placed in a microwave oven or a microwave thawing machine for heating and thawing. This method has a serious corner effect and external heat internal cooling. Therefore, it is easy to damage the quality of frozen products. It is impossible to ensure the freshness of foods, especially in high-end restaurants where food quality and freshness are critical. Existing thawing methods and equipment cannot simultaneously meet the needs of high efficiency, high freshness, and high-quality thawing.

Rapid low-temperature microwave thawing equipment will place the frozen goods in the microwave thawing machine microwave working room, the ambient temperature of the microwave working room is -3 ℃ ~ 3 ℃. In the microwave thawing process, the cold, wet airflow is introduced into the microwave working room, so that the cold, wet airflow condenses into a layer of frost film on the surface of frozen goods. The frozen articles are thawed by microwaves in an environment covered with frost film. Since cold water atomization is used to form a cold and humid airflow, a small amount of water can be used to form a plurality of cooling airflows. At the same time, frozen materials can be placed in the entire microwave working chamber without the limitation of a water tank. It can quickly thaw a large or large number of frozen materials to improve efficiency.

The structure of the fast low-temperature microwave thawing equipment:

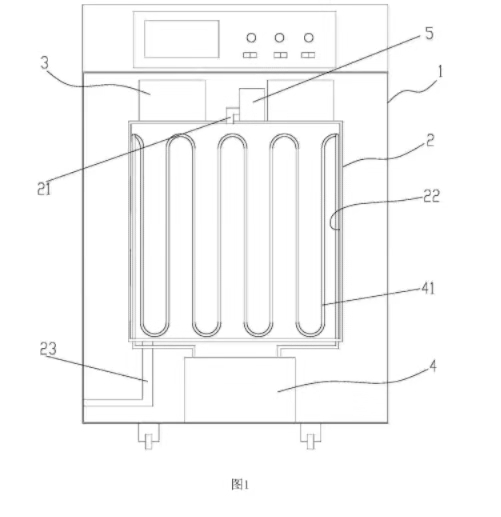

A fast low-temperature microwave thawing equipment comprising a microwave defrosting machine body 1. The microwave defrosting machine body 1 is provided with a microwave working chamber 2 for placing frozen articles and a microwave generator 3 at the periphery. The refrigeration unit 4 is disposed of in the microwave thawing machine body 1. The evaporator 41 of the refrigeration unit 4 is disposed on the inner wall of the microwave working chamber 2. Cooling the microwave working chamber 2 to maintain the temperature in the microwave working chamber 2 at -3 ° C ~ 3 ° C. A cold and humid air inlet 21 is connected to the top of the microwave working chamber 2 and an ultrasonic atomizing humidifier 5 is connected. The ultrasonic atomizing humidifier 5 atomizes the water into water vapor and directly flows into the microwave working chamber 2.

The inner wall surface of the microwave working chamber 2 also adheres with a smooth waterproof membrane 22, which prevents frosting of the cold and wet airflow on the surface and makes the cold and wet airflow more concentrated on the material surface condensation. The bottom of the working chamber 2 is connected with a drainage pipe 23, which is used to discharge the sewage dripping from the material defrosting or the sewage discharged during cleaning.

Of course, the industrialized microwave thawing equipment also needs to use flowmeters, thermometers, hygrometers, and other instrumentation devices and various common parts such as pipeline valves to control and display the temperature and flow of low cold and humid airflow. The water level of the ultrasonic atomizing humidifier is visualized to replenish water in time.

Our first-class service:

1. Our equipment can be customized according to the needs of customers.

2. The low-temperature microwave thawing equipment has a one-year warranty.

3. We can help you install on-site and train your staff.

Our Leader microwave equipment company has been persisting the principle of “quality first, customer first” for many years and is committed to producing environmentally friendly, energy-saving and efficient production equipment. Provide a more complete service. Looking forward to your call!

Compared with traditional thawing equipment, fast low-temperature microwave thawing equipment has many advantages:

Compared with traditional thawing equipment, fast low-temperature microwave thawing equipment has many advantages: Fast low-temperature microwave thawing equipment Technologies and Processing PDF Download

Fast low-temperature microwave thawing equipment Technologies and Processing PDF Download